Temporary Edge Protection Systems are designed to prevent falls from height by safeguarding the area they are fixed to so keeping anyone working within this area safe without any action from them. This is a passive system and is referred to as a Collective safety measure in the Work at Height Hierarchy.

COURSE OVERVIEW

• This course is intended for anyone who Installs, Alters, Dismantles or Inspects Temporary edge protection Systems.

• The Work at Height Hierarchy of controls.

• Legislation – Employers duty of care, Employees responsibilities.

• Equipment selection suitability and inspection.

COURSE CONTENT

When altering or dismantling a Temporary edge protection system the operative can be exposed to open leading edges which means that they will need to connect to a Personal Fall Protection System to ensure that they cannot fall during this work.

During this training course trainees will be shown how to inspect and wear a safety harness with a lanyard and assemble a Work Restraint System, as follows

PERSONAL FALL PROTECTION

1. Selection of appropriate Personal Fall Protection Equipment and compatibility when used as a system.

2. Pre-use inspections of Personal Fall Protection Equipment and how to identify faulty components.

3. Identify damaged or worn components and remove from site.

4. Correct storage, care and cleaning of Personal Fall Protection Equipment.

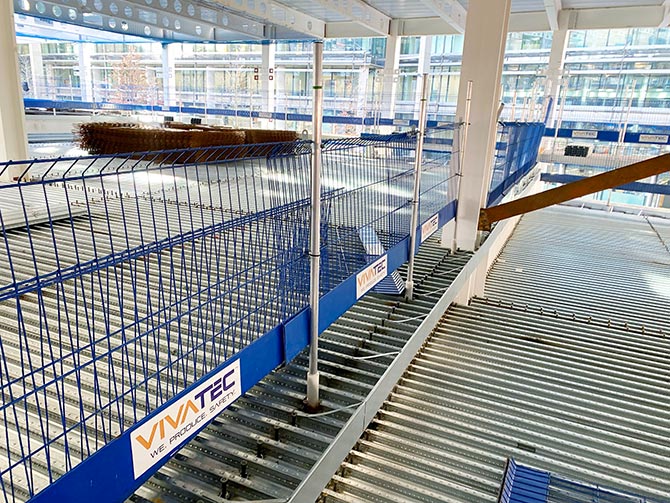

TEMPORARY EDGE PROTECTION

A Temporary Edge Protection System installed around the perimeter of the structure will protect anyone working in this area without them taking any action.

Class A systems

For flat surfaces with a maximum slope up to 10º. The system must resist a horizontal force of 0.3kN anywhere along the top of the Barrier deflecting a maximum of 55mm at the central point of the Barrier. In practical terms this means that the system must support the weight of a person who might be leaning against, walking beside, or at worst, stumbling into the edge protection.

Wind loading

The wind velocity pressure within BS EN 13374 is 0.6N/m2. BS EN 13374 assumes a wind velocity based on 40m height. However, variations will include the physical location, the height of the structure and the duration that the edge protection will stay in place.

SYSTEM AND COMPONENTS

This practical training course comprises:

• Explanation of EN 13374 Class A and its practical parameters.

• Familiarisation of Temporary edge protection components and how they should be installed correctly.

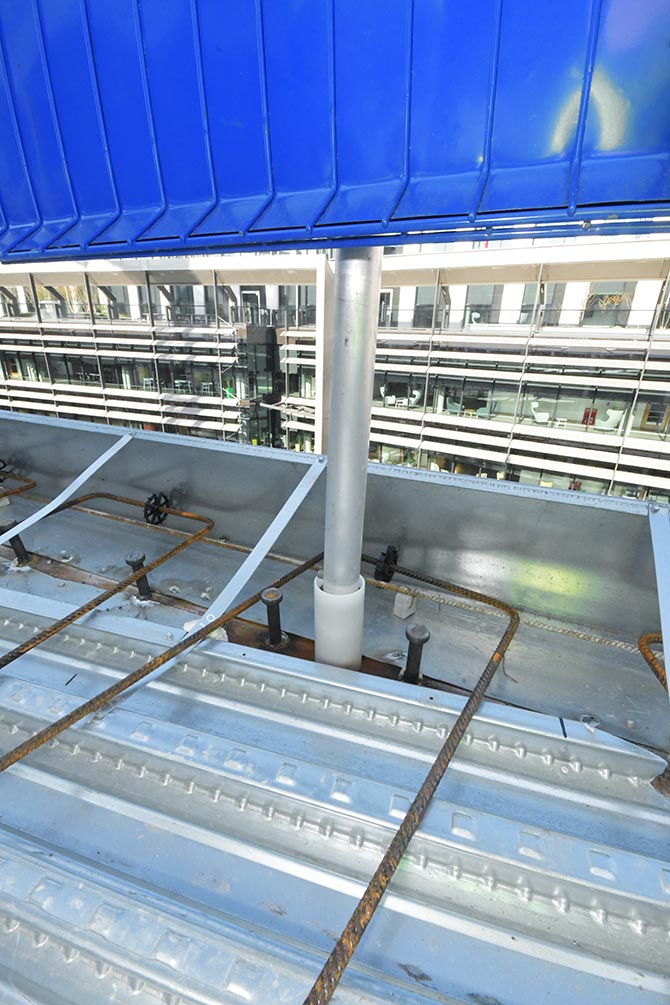

• The system integrity depends on secure and accurate anchorage into the concrete floors, correct installation of Posts and Barriers with methods in place to ensure that Barriers won’t lift in high winds.

Anchors and Anchor Sockets

It is extremely important that anchors are selected, positioned and set, strictly in accordance with the manufacturer’s instructions. Typical Socket Base situations impose a tensile load on the anchor of approximately 6kN, and a shear load of at least 0.3kN for a 1mtr. long post.

Posts

These should have a device or design function to ensure that they can’t be unintentionally lifted from the socket.

TRAINING ENVIRONMENT

This course is conducted in a safe site zone with temporary edge protection in place.

It will need anchor points for a personal safety system to connect to.

CERTIFICATION

Each delegate will be given one to one practical training and upon successful completion will be provided with a certificate with a 36 month validity period.