Our Precast socket is designed to be casted into precast concrete slabs right at the concrete factory. This provide an easier, faster and safer mounting of temporary edge protection at the construction site.

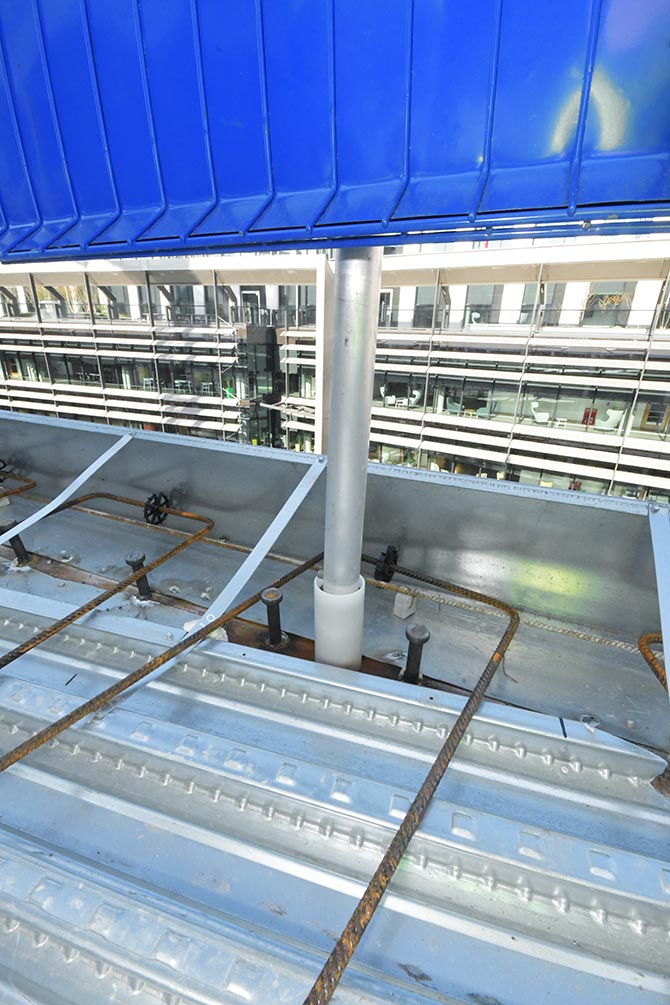

An Omnia flooring slab is a reinforced precast concrete slab which incorporates a triangular lattice girder that is attached to a lower layer of reinforcement. The lattice girder is manufactured using high strength steel wire which binds with in-situ concrete which is poured onto it.

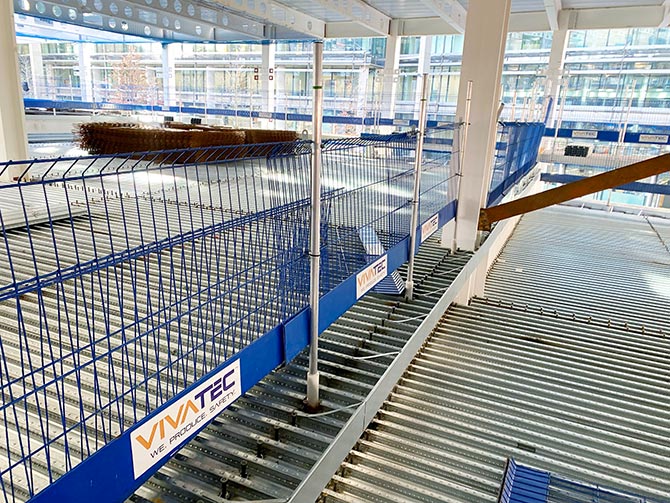

By casting a Precast socket (product code 911108) into the lower slab means that temporary edge protection can be installed onto the slab before it is lifted into position allowing rebar installation and concrete placing onto the slabs within a collectively protected work area.

Precast sockets are fixed to rebar before the lower portion concrete is cast. A cut length of Protective sleeve (product code 911107) is inserted onto the Precast socket, which forms a 50 mm diameter hole around the Post and allows extraction when temporary edge protection is no longer required.

The Precast socket has an integrated post lock. Post 1,3 m and Barrier 2,6 are installed either before or after the prefabricated element is lifted in place. The Barriers can easily be lifted to the desired height when casting. No tools are needed.

PRODUCTS

• Precast socket

• Protection sleeve for Precast socket

• Post 1,3 m

• Barrier 1,3, 2,6

• Frame barrier alu 1,3, 1,95, 2,6

• Frame barrier holder

• Adjustable link bar